Rapid Prototyping

Mareco produces Rapid Prototypes on Micro and Macro level.

Micro Prototypes are small parts with very high building resolustions (16 µm). With this technique very thin wall thicknesses can be achieved. Many micro parts are built in a Ceramic nano-cured Acrylate, a material with high rigidity and high temperature resistance.

See also: Micro Prototyping

With our Objet Multi Material 3D printer we produce 2K parts (overmoulding simulation). A lot of very interesting materials are available: rubber-like material in hardness Shore A 27 up to Shore A 92 and also a high-temperature resistance material.

See also Objet Multi Material 3D Printing

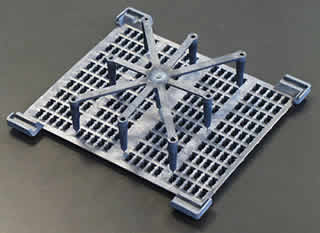

Macro Prototypes are built with our SLS system. These parts are strong and yet highly elastic at the same time. Besides stable and force-absorbing parts, products with film hinges and snap hooks can also be manufactured using this technology.

See also: Macro Prototyping

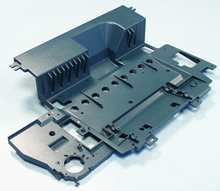

Very often casted parts in Polyurethane give the best solution, for instance if you need a small serie up to 30 or 40 parts. You can make a choice out of several plastic-like PU's, for instance PA-like, ABS-like, PC like and Rubber-like.

See also: Casting in PU

Macro prototype: egg box with elastical hinge

Casted Polyurethane prototype (ABS-like)

Micro prototyping: micro brush, details 0,10 mm