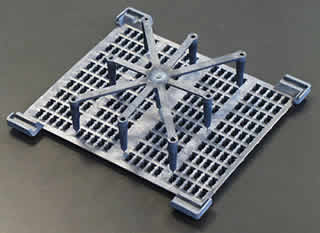

Casting in polyurethane

Polyurethane (or PU) is a copolymer that can be used to manufacture prototypes and series production by casting in silicone moulds. This material comes in many varieties. There is PU with properties that compare to the properties of injection moulding polymers like ABS, Nylon and PC, but there are also polyurethanes for rubber-like applications (Shore 30-90 A).

L+R cover of an ABS-like PU

"Prototyping and/or series production"

The silicone mould is made on the basis of an 'original model', which is the product you would like to 'copy' once or several times. Depending on size and shape, we make the original model using our DLP/DMD technology, stereo lithography or Selective Laser Sintering.

Depending on the shape of the product (few or many undercuts) and the polyurethane grade, 30 to 50 casts can be made per silicone mould.

See also our technology matrix.

The following options are also possible:

- transparent products

- products that conduct electric current

- products that are coloured according to several RAL numbers

Product specifications:

- Maximum product dimensions 830 x 530 x 600 [mm] (not glued)

- Dimensional accuracy ± 0.01 to 0.4% per 100 [mm] (depending on size and shape)