Prototypes and resolutions at Mareco

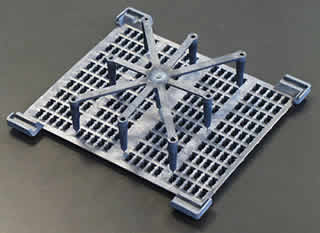

When making prototypes using a 'layer manufacturing' technology, the layer thickness used is important for the vertical resolution. The standard layer thickness with Selective Laser Sintering is 0.10 [mm]; with Micro Prototyping layer thicknesses vary from 0.016 to 0.10 [mm].

When using SLS, the horizontal resolutions are determined by the spot diameter and the resulting melt process, whereas for Micro Prototyping this is determined by the pixel resolution and the ERM (Enhanced Resolution Mode) method used.

See the different technologies by using the submenus on the right-hand side.